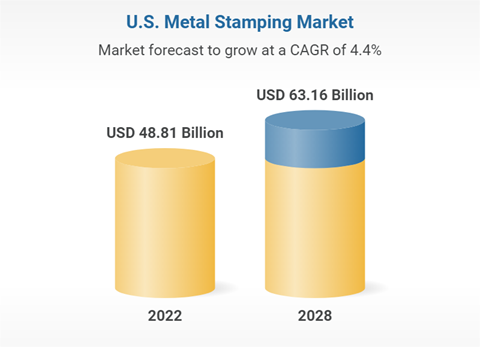

U.S. Metal Stamping Market – Focused Insights 2023-2028

The metal stamping industry in the United States is poised for remarkable growth, with a projected valuation of approximately $63.16 billion by 2028, compared to $48.81 billion in 2022. This promising expansion is expected to occur at a compound annual growth rate (CAGR) of 4.4%. In this comprehensive article, we delve into the factors driving this growth and the dynamics that shape the U.S. metal stamping market.

1. Rising Demand Across Diverse Industries

The notable expansion of the metal stamping market in the United States is due to the strong manufacturing sector and the rising demand for metal components in a broad array of industries. This includes automotive, industrial machinery, aerospace, electrical & electronics, construction, medical, and more.

2. Automotive Industry Dominance

The automotive sector stands out as one of the primary consumers of metal stamping products in the United States. The shift towards lightweight and intricate automobile components has been a significant driver of market growth. Precision metal components are essential for enhancing fuel efficiency and overall vehicle performance.

3. Aerospace and Defense Contributions

Aside from the automotive industry, the aerospace and defense sectors have also played a significant role in the United States. The need for precision components in aircraft and defense equipment is paramount, driving the demand for metal stamping solutions.

4. Technological Advancements Fuel Growth

Advancements in stamping technology have played a pivotal role in boosting productivity and quality within the metal stamping industry. High-speed stamping machines, CNC technology, and automation have transformed manufacturing processes, enhancing their efficiency and precision.

5. Competitive Landscape

The U.S. metal stamping market is highly competitive, featuring both established giants and numerous small-scale manufacturers. Competition is fierce, pushing companies to constantly innovate and improve their offerings.

6. Regulatory and Quality Standards

Strict regulatory and quality standards govern the metal stamping industry, particularly in sectors such as automotive, aerospace, and medical. Safety and reliability are imperative, underscoring the significance of strict adherence to these standards.

7. Global Trade Dynamics

The market is also influenced by global trade dynamics, including tariffs and international agreements. These factors have a significant impact on the import and export of metal components and raw materials, shaping the market’s trajectory.

8. Ongoing Market Changes

The U.S. metal stamping market is continuously evolving due to economic conditions, technological advancements, and shifts in demand across end-user industries. To stay competitive, players in the industry should prioritize technological innovation, sustainability, and adaptability to shifting market dynamics.

In conclusion, the U.S. metal stamping market is on a trajectory of robust growth, driven by the diverse demand from various industries, technological advancements, and strict adherence to quality standards. To prosper in this competitive setting, businesses must maintain their agility, foster innovation, and promptly adapt to the ever-evolving market conditions.

FAQs

1. What is metal stamping?

Metal stamping is a manufacturing process that involves shaping metal sheets or coils into specific forms using stamping presses and dies. It is commonly used to create parts and components for various industries.

2. Why is the automotive industry a significant consumer of metal stamping products?

The automotive industry relies on metal stamping for the production of lightweight and intricate components, which are essential for improving fuel efficiency and overall vehicle performance.

3. How do technological advancements impact the metal stamping industry?

Technological advancements, such as high-speed stamping machines and automation, enhance productivity and quality in the metal stamping industry, making it more efficient and precise.

4. How can metal stamping businesses adapt to changing market dynamics?

To adapt to changing market dynamics, metal stamping companies should focus on technological innovation, sustainability, and agility to remain competitive and meet the diverse demands of various industries.