Precision metal stamping is a special process that applies pressure to metal materials to produce parts or semi-finished products that meet specific requirements. With the increasing quality standards for mechanical and electronic equipment components, precision metal stamping is currently a widely used manufacturing process in metal parts processing.

Compared to other methods of mechanical and plastic processing, precision metal stamping has unique advantages in both technical and economic aspects.

So, what are the advantages of precision metal stamping?

1- High production efficiency

High production efficiency of stamping processing, easy operation, and easy realization of mechanization and automation. This is because stamping relies on dies and stamping equipment to complete the processing. The stroke frequency of a conventional press can reach dozens of times per minute, while high-speed presses can reach several hundred or even thousands of times per minute. Each stamping stroke can produce a stamped part.

2- High accuracy

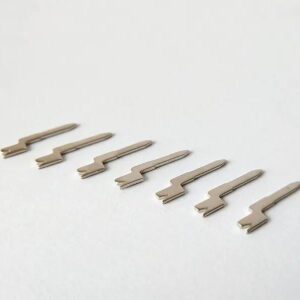

During stamping, the dimensions and shape accuracy of the stamped parts are ensured by the dies, and the surface quality of the stamped parts is generally not compromised. Since the die’s lifespan is generally long, the quality of stamping is stable, with good interchangeability and the characteristic of being “exactly the same.”

3- Wide processing range

Stamping can process parts with a large size range and complex shapes, from small parts like watch second hands to large parts like automobile longitudinal beams and covers. Additionally, due to the cold deformation hardening effect of the material during stamping, the strength and rigidity of the stamped parts are high.

4- Energy-saving and low cost

Stamping generally does not generate scrap, resulting in less material consumption and not requiring additional heating equipment. Therefore, it is a cost-effective and energy-saving processing method, leading to lower production costs for stamped parts.

Looking back over the past few decades, the development of the manufacturing industry has gone from nothing to flourishing, greatly improving people’s material living standards. Now, in the era of information technology, the rapid pace of technological advancement is self-evident. Stamped parts will have great prospects in the application of 5G communication cabinets and intelligent robots.

1- 5G Communication Cabinets in the 5G Era

The 5G era is a feast of communication technology. The interval between each update is ten years, but this may be shortened in the future. It is a basic requirement for military, defense, and people’s livelihood, equally important as water and electricity. Nowadays, with widespread commercial use, there is a need to deploy 5G communication cabinets extensively across the country to ensure the subsequent signal transmission of various 5G devices. As a component of the chassis, there will be endless demand for precision metal stamping parts. In terms of product characteristics, attention will be focused on quality issues because this type of base station equipment is installed outdoors for long periods and needs to withstand issues such as wind and sun, with a long service life.

2- Intelligent Robots

With the automation upgrade, intelligent robots are now widely used in the production, packaging, and handling of many products. Their benefits are obvious: high efficiency, good quality, and long-term operation. The logistics industry is a major application area. In large logistics warehouses, tens of thousands of goods are instructed by the data center to perform a series of actions for each robot, including accurate storage and placement, as well as picking and shipping. Precision metal stamping parts are important components in this process. The flexibility and durability of the robots, especially the operation of the robot joints, are crucial. The metal parts not only need to have moderate hardness and good metal ductility but also need to have characteristics such as oxidation resistance and corrosion resistance. It is evident that there is a broad development prospect.